Valve clearance Question

Forum rules

Please can you post items for sale or wanted in the correct For Sale section. Items / bikes for sale here will be removed without warning. Reasons for this are in the FAQ. Thanks

Please can you post items for sale or wanted in the correct For Sale section. Items / bikes for sale here will be removed without warning. Reasons for this are in the FAQ. Thanks

- Cal Walker

- Site Supporter

- Posts: 128

- Joined: Fri Apr 12, 2013 4:04 pm

- Bike owned: NC30, CRF450R Supermoto

- Location: Peterborough, United Kingdom

Valve clearance Question

Hi guys,

Just one quick question and I think I'm having a blonde moment! or stupid!

or stupid!

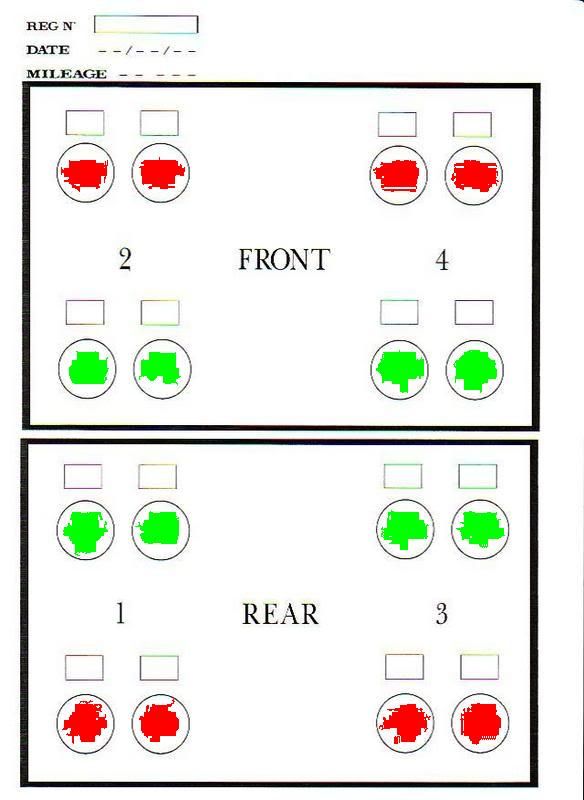

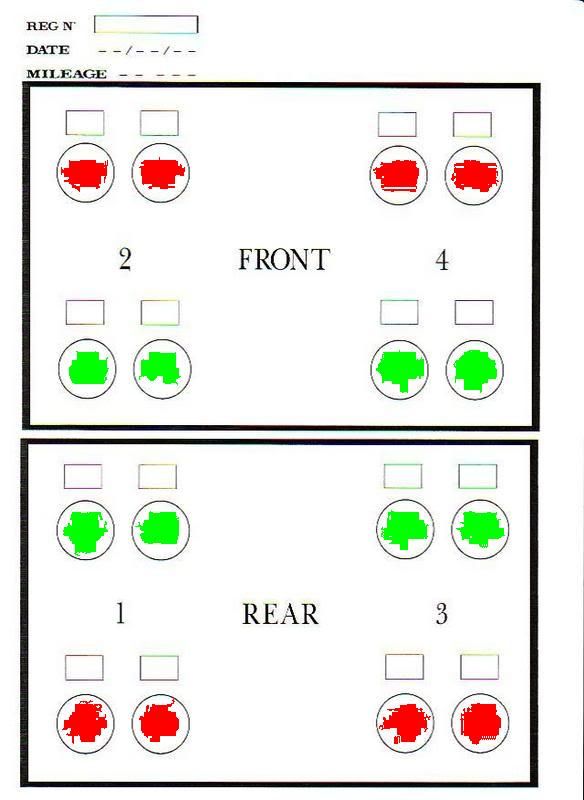

Am I right in thinking that the circles in green are the inlet valves and the circles in red are exhaust valves?

Many thanks....Cal

Just one quick question and I think I'm having a blonde moment!

Am I right in thinking that the circles in green are the inlet valves and the circles in red are exhaust valves?

Many thanks....Cal

- 28hodge

- Site Supporter

- Posts: 650

- Joined: Tue May 17, 2011 4:26 pm

- Bike owned: nc30 (track) Yam YZ250 (MX)2st

- Location: Kendal, Cumbria, Northwest

Re: Valve clearance Question

yeah thats right,

The valves nearest the carbs are the inlets the ones nearest the exhausts are the outlet/exhaust valves.

The valves nearest the carbs are the inlets the ones nearest the exhausts are the outlet/exhaust valves.

- Cal Walker

- Site Supporter

- Posts: 128

- Joined: Fri Apr 12, 2013 4:04 pm

- Bike owned: NC30, CRF450R Supermoto

- Location: Peterborough, United Kingdom

Re: Valve clearance Question

Cheers buddy!

Regards....Cal

Regards....Cal

- Cal Walker

- Site Supporter

- Posts: 128

- Joined: Fri Apr 12, 2013 4:04 pm

- Bike owned: NC30, CRF450R Supermoto

- Location: Peterborough, United Kingdom

Re: Valve clearance Question

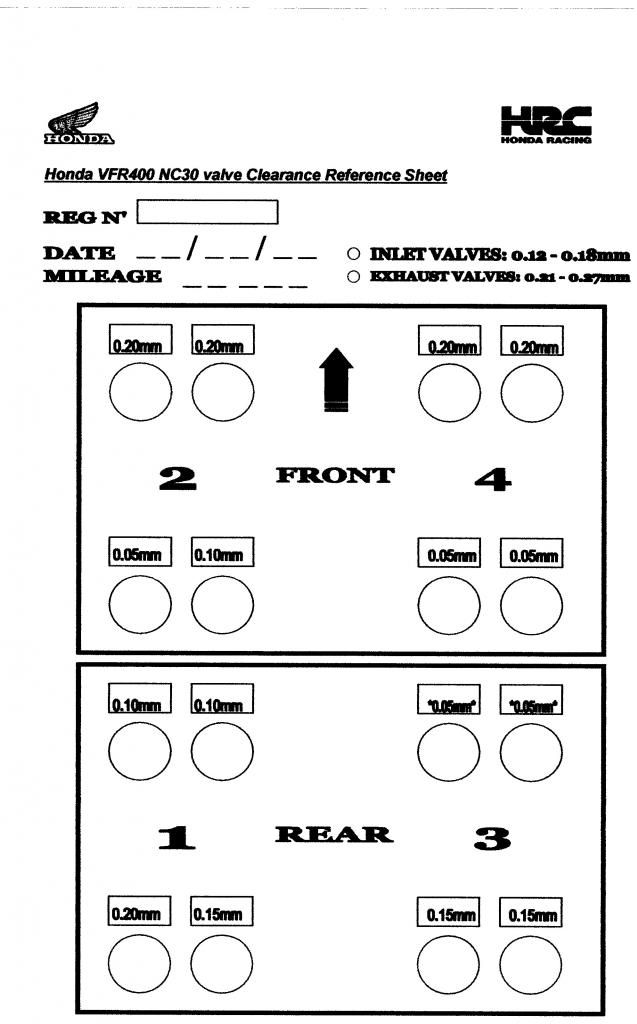

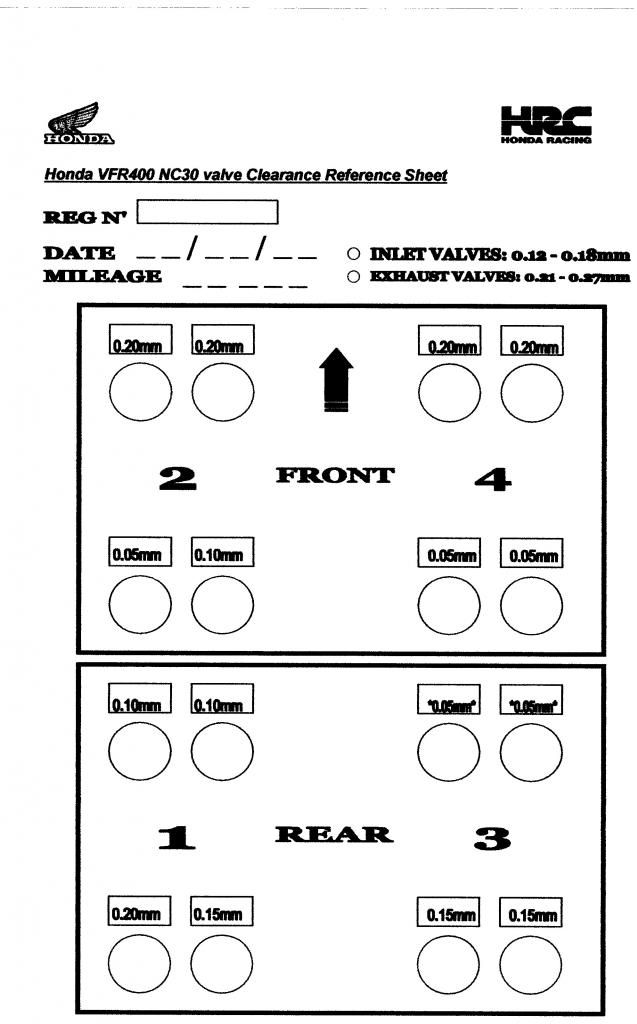

Right...... just been out having a fiddle with my spare engine. Just did a quick valve clearance check and the results are as follows:

As I'm a bit new to this and am learning, I can see that I have none within the stated clearances, there all under. On the inlet valves on cylinder 3 I couldn't even get a 0.05mm feeler in there? (the measurement with the * either side)

So I'm basically asking if all my shims are under do they all need replacing to put them in them in the middle of the stated clearances?

Many thanks....Cal

As I'm a bit new to this and am learning, I can see that I have none within the stated clearances, there all under. On the inlet valves on cylinder 3 I couldn't even get a 0.05mm feeler in there? (the measurement with the * either side)

So I'm basically asking if all my shims are under do they all need replacing to put them in them in the middle of the stated clearances?

Many thanks....Cal

- 28hodge

- Site Supporter

- Posts: 650

- Joined: Tue May 17, 2011 4:26 pm

- Bike owned: nc30 (track) Yam YZ250 (MX)2st

- Location: Kendal, Cumbria, Northwest

Re: Valve clearance Question

Have you done them as per the Haynes as it has an error in it with the way it explains to measure the clearances.

Make sure you are measuring the clearance between the rocker and the actual shim and not as per the Haynes description that tells you to measure it between the cam and the rocker arm I think!

Make sure you are measuring the clearance between the rocker and the actual shim and not as per the Haynes description that tells you to measure it between the cam and the rocker arm I think!

- Cal Walker

- Site Supporter

- Posts: 128

- Joined: Fri Apr 12, 2013 4:04 pm

- Bike owned: NC30, CRF450R Supermoto

- Location: Peterborough, United Kingdom

Re: Valve clearance Question

Yeah followed the Haynes manual to the T, but I did measure between the rocker arm and the shim.

Cheers......Cal

Cheers......Cal

-

racingt

- NWAA Supporter

- Posts: 178

- Joined: Sun Jun 12, 2011 12:02 pm

- Bike owned: NC35, Shand Stoater plus

- Location: Cambridgeshire

Re: Valve clearance Question

Cal, I'm new at this too and practised on my spare engine on Sunday. I measured using the feeler gauge along the cam, all clearances were .05 mill tighter than measuring directly on top of the shim to rocker arm. In other word, if my feeler gauge was in The middle of the gears, I was measuring correctly. If I inserted it from the outside, then it was wrong. Hope that communicates adequately what I was doing.

If you have done it correctly, and it's worth checking, again, then I guess yes you need shims.

Desperate to start this work on my working motor, now, but there is never enough time is there!

Hope that was of help.

Phil

If you have done it correctly, and it's worth checking, again, then I guess yes you need shims.

Desperate to start this work on my working motor, now, but there is never enough time is there!

Hope that was of help.

Phil