Ok, flywheel removed for total loss. Here is what I did

Forum rules

Please can you post items for sale or wanted in the correct For Sale section. Items / bikes for sale here will be removed without warning. Reasons for this are in the FAQ. Thanks

Please can you post items for sale or wanted in the correct For Sale section. Items / bikes for sale here will be removed without warning. Reasons for this are in the FAQ. Thanks

-

StrayAlien

- Familiar Member

- Posts: 361

- Joined: Sun Jan 15, 2012 9:27 am

- Bike owned: NC30, Dukes, Hog

- Location: Melbourne, Straya

Ok, flywheel removed for total loss. Here is what I did

Further to this thread:

viewtopic.php?f=24&t=42053

I have removed the flywheel but left the stator in place. The kilo will not make a difference to me at this stage - but I sure didn't want to dick around with sealing the grommit. So, it is all left there with only the flywheel being removed.

Gone:

And here is how much rotating mass was involved:

Quite a bit. I am a bit crap at race starts, and this will likely make me more crap ... so I better get practicing!

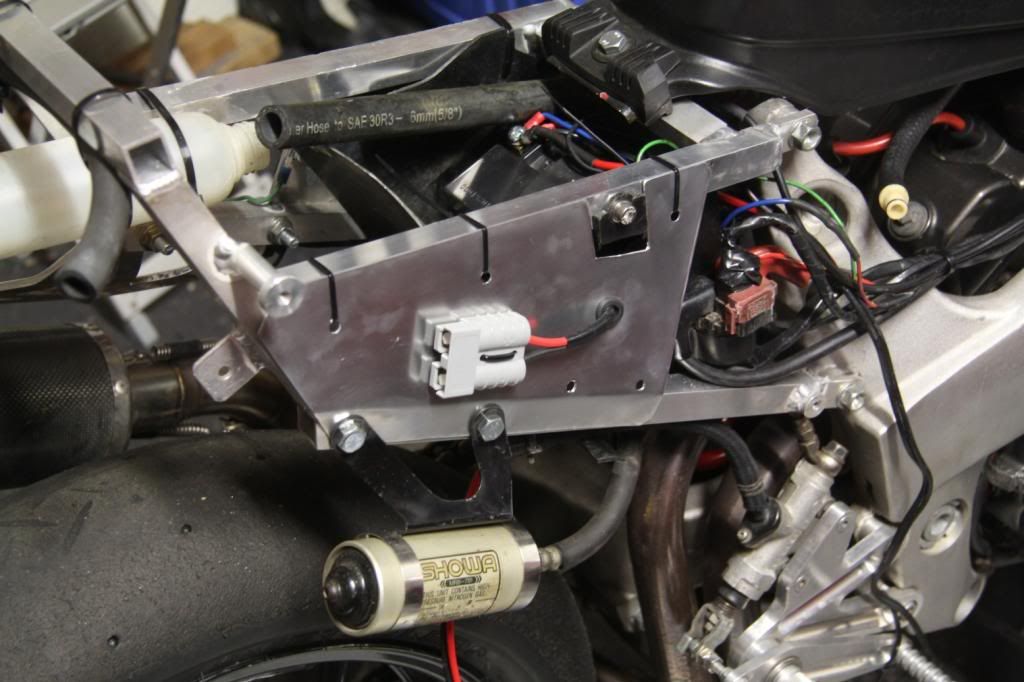

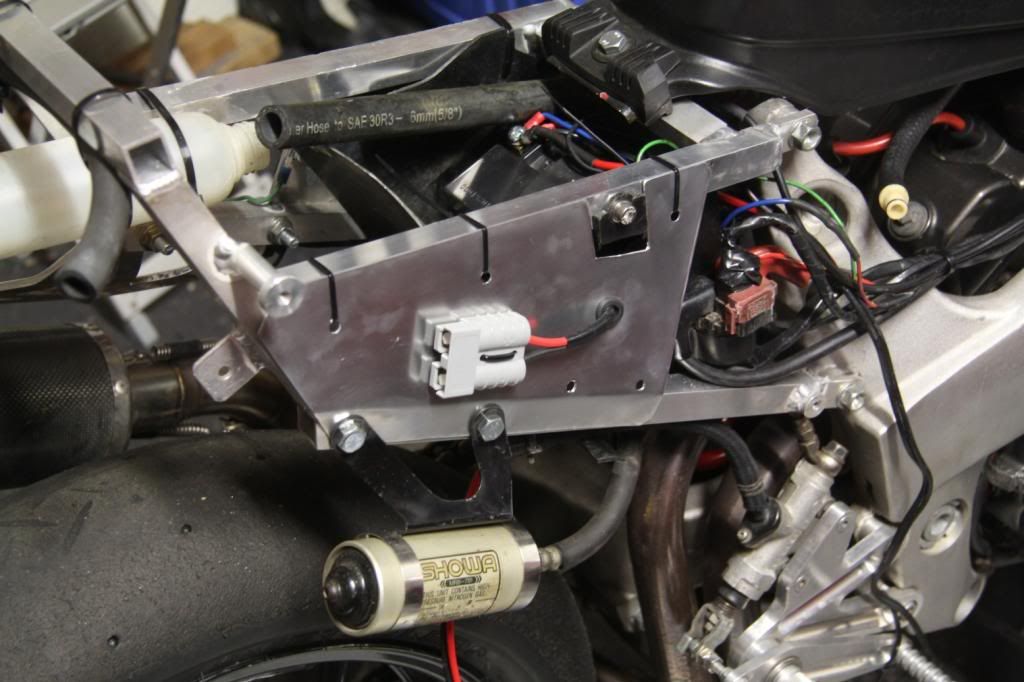

As people have said the downside is buggering about with battery and charging crap at the track. Forum member 999Gomerz suggested I install an 'Anderson' plug and use that to connect to a starter, or battery tender or whatever. Anderson plugs are durable high-amperage connectors. So I have. Here is the result (I have an RO subframe):

I made a aluminum plate for the right side of the subframe to mount the connector. It looks like a lot of real-estate for a single plug, but I wanted to to be easy to get at under the seat cowl with no mucking about and I wanted it to be shielded as well as I could from wheel/water etc (also, I have a rubber end-plug for it on order). I could have tied it to the subframe but the result was a bit wobbly, exposed, and not that great. The fabrication is a bit crap, I am pretty new to this stuff, but I am happy with the result.

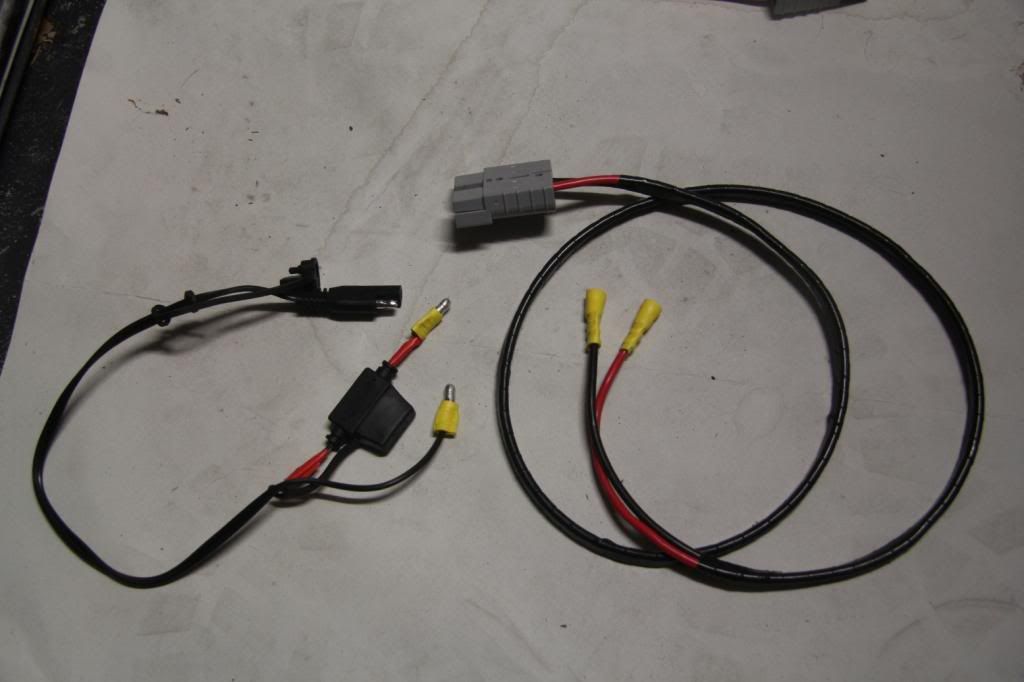

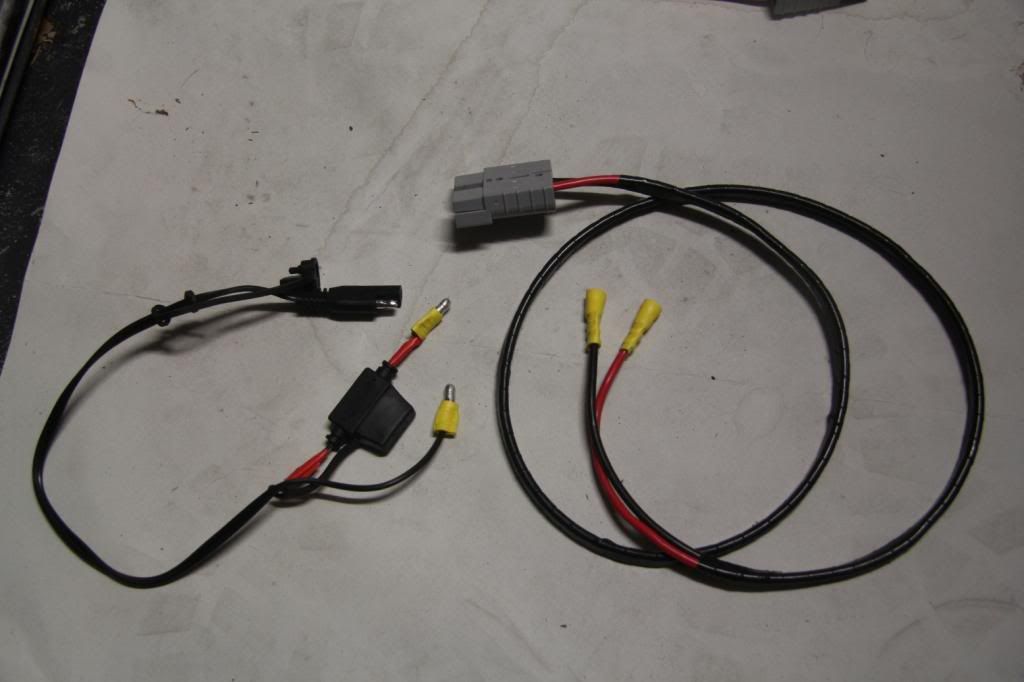

I normally take a spare battery with me to the track to help with starting if things go wrong. It is a Ducati 999 battery so it has some grunt. I wired it up to another Anderson connector so I can just plug the damn thing in to help the bike get started if required.

Also, for the trickle charger I used another Anderson connector and also butchered an SAE connector trickle charger lead with plugs so I can use my other (non-SAE connector) trickle charger without redoing the Anderson connector:

.

.

Next Sunday is a race day with no track time in between so wish me luck that it all hangs together!

.. and thanks for your help everybody.

viewtopic.php?f=24&t=42053

I have removed the flywheel but left the stator in place. The kilo will not make a difference to me at this stage - but I sure didn't want to dick around with sealing the grommit. So, it is all left there with only the flywheel being removed.

Gone:

And here is how much rotating mass was involved:

Quite a bit. I am a bit crap at race starts, and this will likely make me more crap ... so I better get practicing!

As people have said the downside is buggering about with battery and charging crap at the track. Forum member 999Gomerz suggested I install an 'Anderson' plug and use that to connect to a starter, or battery tender or whatever. Anderson plugs are durable high-amperage connectors. So I have. Here is the result (I have an RO subframe):

I made a aluminum plate for the right side of the subframe to mount the connector. It looks like a lot of real-estate for a single plug, but I wanted to to be easy to get at under the seat cowl with no mucking about and I wanted it to be shielded as well as I could from wheel/water etc (also, I have a rubber end-plug for it on order). I could have tied it to the subframe but the result was a bit wobbly, exposed, and not that great. The fabrication is a bit crap, I am pretty new to this stuff, but I am happy with the result.

I normally take a spare battery with me to the track to help with starting if things go wrong. It is a Ducati 999 battery so it has some grunt. I wired it up to another Anderson connector so I can just plug the damn thing in to help the bike get started if required.

Also, for the trickle charger I used another Anderson connector and also butchered an SAE connector trickle charger lead with plugs so I can use my other (non-SAE connector) trickle charger without redoing the Anderson connector:

.

.Next Sunday is a race day with no track time in between so wish me luck that it all hangs together!

.. and thanks for your help everybody.

-

RoninZX-10R

- Settled in member

- Posts: 216

- Joined: Tue Jul 07, 2009 1:50 am

- Bike owned: NC35 racebike, ZX10R roadbike

- Location: Melbourne, Australia

Re: Ok, flywheel removed for total loss. Here is what I did

Looks good. I've been thinking about trying this myself on my RVF racebike, but now I've got a baby on the way (due in about 4 weeks) so my racing days are slightly curtailed for a little while at least.

Let us all know how the bike performs. Are racing at the interclub up in Broadford this weekend?

Let us all know how the bike performs. Are racing at the interclub up in Broadford this weekend?

-

StrayAlien

- Familiar Member

- Posts: 361

- Joined: Sun Jan 15, 2012 9:27 am

- Bike owned: NC30, Dukes, Hog

- Location: Melbourne, Straya

Re: Ok, flywheel removed for total loss. Here is what I did

Hey mate, yep Broadford interclub at the weekend. I promose a full report on the mods. :-)

-

RoninZX-10R

- Settled in member

- Posts: 216

- Joined: Tue Jul 07, 2009 1:50 am

- Bike owned: NC35 racebike, ZX10R roadbike

- Location: Melbourne, Australia

Re: Ok, flywheel removed for total loss. Here is what I did

So how'd you go at the Interclub? Do you think the lack of flywheel weight made much difference?

-

StrayAlien

- Familiar Member

- Posts: 361

- Joined: Sun Jan 15, 2012 9:27 am

- Bike owned: NC30, Dukes, Hog

- Location: Melbourne, Straya

Re: Ok, flywheel removed for total loss. Here is what I did

Well, not the greatest of weekends ... i broke my collarbone! Worse thing is, I'll be okay in 6 weeks, but the poor bike is a mess. Bent forks, the works. Geeez. I am okay though, so no issues apart from getting used to doing everything with my left hand. Stop chortling in the back row ...

In a way, the flywheel mod was a contributing factor but the simple fact is the crash was my fault. Cooling track, poor rear suspension setup, and a bike now capable of breaking traction with big handfuls of throttle. And I gave it a big handful when I should have been more gentle.

Initially, I thought the mod did not make much of a difference - Broadford is a track where you use gear ratios like a tractor and the engine is always spinning high. But after the second session it dawned on me - i was consistently doing about 2 seconds a lap faster than the last time I was there a month ago. I am not an expert rider and was having some difficulty breaking that 1:10 barrier there, last trip I was bashing out low 1:10s cookie cutter laps and manage to fluke a 1.08, now I was bashing out low 1:08s cookie cutter laps.

Oh ... mmmm.

Third session out, I found the rear tyre could break traction on a dry surface under throttle. I think that was not totally the flywheel mod, but a combination of things on the day that included the flywheel mod. But ... coming down the hill from turn 4 ('crash corner'), as I hit the gas I could get the front wheel off the ground - there was NO WAY that would have happened before.

I guess, really, it makes the engine feels more (to me) like it should anyways. It does spin quicker and in a way makes it feel there there is more horsepower - when there ain't.

And, even with my little non-LiOn $60 battery, I could get a good charge between sessions and had no issues at all. Over lunch break, the battery tender on it got back to 'green'. As I came in from each session, I just hooked up the anderson connector jobby above and it was all good.

But, as a piece of advice, you have to consider the flywheel mod as part of a larger package - you may need to alter your suspension and/or riding style and the way you tackle some familiar corners - especially high lean angle off camber double apexes. :-) .. at least that is the way I look at it, others may differ.

The poor bike is going to need a lot of love and I am out of racing until I heal and the bike is repaired - but I'll be keeping the flywheel off.

... and hopefully by then I'll have my replica HRC linkage and a shock to suit. :-)

In a way, the flywheel mod was a contributing factor but the simple fact is the crash was my fault. Cooling track, poor rear suspension setup, and a bike now capable of breaking traction with big handfuls of throttle. And I gave it a big handful when I should have been more gentle.

Initially, I thought the mod did not make much of a difference - Broadford is a track where you use gear ratios like a tractor and the engine is always spinning high. But after the second session it dawned on me - i was consistently doing about 2 seconds a lap faster than the last time I was there a month ago. I am not an expert rider and was having some difficulty breaking that 1:10 barrier there, last trip I was bashing out low 1:10s cookie cutter laps and manage to fluke a 1.08, now I was bashing out low 1:08s cookie cutter laps.

Oh ... mmmm.

Third session out, I found the rear tyre could break traction on a dry surface under throttle. I think that was not totally the flywheel mod, but a combination of things on the day that included the flywheel mod. But ... coming down the hill from turn 4 ('crash corner'), as I hit the gas I could get the front wheel off the ground - there was NO WAY that would have happened before.

I guess, really, it makes the engine feels more (to me) like it should anyways. It does spin quicker and in a way makes it feel there there is more horsepower - when there ain't.

And, even with my little non-LiOn $60 battery, I could get a good charge between sessions and had no issues at all. Over lunch break, the battery tender on it got back to 'green'. As I came in from each session, I just hooked up the anderson connector jobby above and it was all good.

But, as a piece of advice, you have to consider the flywheel mod as part of a larger package - you may need to alter your suspension and/or riding style and the way you tackle some familiar corners - especially high lean angle off camber double apexes. :-) .. at least that is the way I look at it, others may differ.

The poor bike is going to need a lot of love and I am out of racing until I heal and the bike is repaired - but I'll be keeping the flywheel off.

... and hopefully by then I'll have my replica HRC linkage and a shock to suit. :-)

-

RoninZX-10R

- Settled in member

- Posts: 216

- Joined: Tue Jul 07, 2009 1:50 am

- Bike owned: NC35 racebike, ZX10R roadbike

- Location: Melbourne, Australia

Re: Ok, flywheel removed for total loss. Here is what I did

Ahh bugger, sorry to hear about your crash. How did it happen, coming out of Crash Corner?

But that's a good sign that you were able to consistently drop 2 seconds from your personal best...nice work.

Good luck with the rehabilitation, hopefully you'll be up and about in no time. When I wrecked my shoulder the doctor told me to keep the shoulder mobile, don't just keep it wrapped up in a sling for too long (although admittedly mine wasn't a broken collar bone, just ripped the tendons apart when the back end of my ZX-10R slammed into me...but that's another bedtime story!)

But that's a good sign that you were able to consistently drop 2 seconds from your personal best...nice work.

Good luck with the rehabilitation, hopefully you'll be up and about in no time. When I wrecked my shoulder the doctor told me to keep the shoulder mobile, don't just keep it wrapped up in a sling for too long (although admittedly mine wasn't a broken collar bone, just ripped the tendons apart when the back end of my ZX-10R slammed into me...but that's another bedtime story!)

-

StrayAlien

- Familiar Member

- Posts: 361

- Joined: Sun Jan 15, 2012 9:27 am

- Bike owned: NC30, Dukes, Hog

- Location: Melbourne, Straya

Re: Ok, flywheel removed for total loss. Here is what I did

Heya, exit of turn 1 actually.

The arm will be fine, but the bike is a bit bent up - forks bent etc. But bike and me will be okay in 8 weeks or so. One of the club racers is coming over on Wednesday to help gets bits off it so I can begin the fixing process. Very nice of him. The big karmic wheel in action. Beers.

I can offer one bit of advice to Victorian racers - when you go to hospital and they ask you what speed you where going, if you say more than 30kph they will do a FULL TRAUMA assessment on you. MRI, ultrasound, xrays etc.

That is okay, but the WORST thing is they assume you ARE traumatically injured and then set about proving you are not. So, you get a drip (yes!) and a neck brace (yes!) and immobilised until they are satisfied you are okay. Despite the fact that you can move you neck fine and there is no pain etc etc, and that doctors have come in en examined you agreed there seems to be no other injuries, you have to pretend you are hurt while they get 5 people to roll you over and move between beds all night etc etc. Pure idiocy.

It took 15 HOURS to do all that!!!

So, on Sunday eve I walk in (compos mentis) and say I have a broken collarbone, and I am standing there saying it, then after the 'how fast' question that was it. On a tray and into trauma. Drip, brace, etc etc. 15 hours.

The funny thing is, I walked in with a sling on all okay except for shoulder, then 15 hours later walked out with a sling all okay except for the shoulder. Geeeez!

Be warned!! :-)

PS. In case you are wondering, the sling was from the parameds at the track. Tthere was a previous accident and they said that another ambulance might be 2-3 hours away. All agreed that I was okay (except for shoulder) so they agreed I could self-admit to hospital on arrival back to Melbourne - some other people packed up my stuff and drove it back. More karma.

The arm will be fine, but the bike is a bit bent up - forks bent etc. But bike and me will be okay in 8 weeks or so. One of the club racers is coming over on Wednesday to help gets bits off it so I can begin the fixing process. Very nice of him. The big karmic wheel in action. Beers.

I can offer one bit of advice to Victorian racers - when you go to hospital and they ask you what speed you where going, if you say more than 30kph they will do a FULL TRAUMA assessment on you. MRI, ultrasound, xrays etc.

That is okay, but the WORST thing is they assume you ARE traumatically injured and then set about proving you are not. So, you get a drip (yes!) and a neck brace (yes!) and immobilised until they are satisfied you are okay. Despite the fact that you can move you neck fine and there is no pain etc etc, and that doctors have come in en examined you agreed there seems to be no other injuries, you have to pretend you are hurt while they get 5 people to roll you over and move between beds all night etc etc. Pure idiocy.

It took 15 HOURS to do all that!!!

So, on Sunday eve I walk in (compos mentis) and say I have a broken collarbone, and I am standing there saying it, then after the 'how fast' question that was it. On a tray and into trauma. Drip, brace, etc etc. 15 hours.

The funny thing is, I walked in with a sling on all okay except for shoulder, then 15 hours later walked out with a sling all okay except for the shoulder. Geeeez!

Be warned!! :-)

PS. In case you are wondering, the sling was from the parameds at the track. Tthere was a previous accident and they said that another ambulance might be 2-3 hours away. All agreed that I was okay (except for shoulder) so they agreed I could self-admit to hospital on arrival back to Melbourne - some other people packed up my stuff and drove it back. More karma.

-

Morespeedvicar

- Site Supporter

- Posts: 837

- Joined: Thu May 01, 2008 1:37 am

- Bike owned: Fzr400, NC30, CB50J, SS50Z KLR

- Location: Grimsby

Re: Ok, flywheel removed for total loss. Here is what I did

Better to be safe than sorry tho dude, at least now you know theres no hidden injuries! All the best an get well soon.

Cheers

Ian

Cheers

Ian

-

RoninZX-10R

- Settled in member

- Posts: 216

- Joined: Tue Jul 07, 2009 1:50 am

- Bike owned: NC35 racebike, ZX10R roadbike

- Location: Melbourne, Australia

Re: Ok, flywheel removed for total loss. Here is what I did

Turn 1 at Broadford has caught a few people out, the exit is quite off-camber and when you pin the throttle (usually doesn't seem to bother my RVF) you can low side pretty easily. Is that what happened to you?

I really like your set-up with the Anderson connectors, etc, looks nice and neat. I might have to give it a go myself one of these days.

How's the rehabilitation going, everything still fairly sore I'm guessing???

I really like your set-up with the Anderson connectors, etc, looks nice and neat. I might have to give it a go myself one of these days.

How's the rehabilitation going, everything still fairly sore I'm guessing???

-

StrayAlien

- Familiar Member

- Posts: 361

- Joined: Sun Jan 15, 2012 9:27 am

- Bike owned: NC30, Dukes, Hog

- Location: Melbourne, Straya

Re: Ok, flywheel removed for total loss. Here is what I did

Hiya,

I'm pretty good actually. Not too sore at all. I've had a few "oh f*ck!" moments in bed at night but all okay, I don't quite have the shoulder strength to do much work on the bike. However, a fellow NC30 racer came over last night to help me get forks out and apart and carbs out. Bless. What goes around come around. Good on him, I owe him one.

Turn 1 lowside? Not quite, got a slide, then it hooked, then I didn't highside but got a wobble then ran out of road. I am sure that turn 1 exit has caught many people in the same way .. just goes off camber as you exit.

Funny you know, I used to think of Broadford as some 'second-cousin' poor place to go to when you couldn't get to Phillip Island. Now, I prefer it. If you can get around Broadford fast you have learned a thing or three. A great and challenging track.

The bike (the 'Bee' as the good lady calls it) needs some repairs, so I am about to post my first 'what about this bit' on this forum. :-)

The Anderson connector thing worked well. I got mine from jcar - the 50amp one. Much cheaper than other places and the real item - not a fake. The rubber cap is a must. Seals well and protect connector from grime. I got them from here:

http://andersonpower.com.au/

I'm pretty good actually. Not too sore at all. I've had a few "oh f*ck!" moments in bed at night but all okay, I don't quite have the shoulder strength to do much work on the bike. However, a fellow NC30 racer came over last night to help me get forks out and apart and carbs out. Bless. What goes around come around. Good on him, I owe him one.

Turn 1 lowside? Not quite, got a slide, then it hooked, then I didn't highside but got a wobble then ran out of road. I am sure that turn 1 exit has caught many people in the same way .. just goes off camber as you exit.

Funny you know, I used to think of Broadford as some 'second-cousin' poor place to go to when you couldn't get to Phillip Island. Now, I prefer it. If you can get around Broadford fast you have learned a thing or three. A great and challenging track.

The bike (the 'Bee' as the good lady calls it) needs some repairs, so I am about to post my first 'what about this bit' on this forum. :-)

The Anderson connector thing worked well. I got mine from jcar - the 50amp one. Much cheaper than other places and the real item - not a fake. The rubber cap is a must. Seals well and protect connector from grime. I got them from here:

http://andersonpower.com.au/