nc21 exhaust

Forum rules

Please can you post items for sale or wanted in the correct For Sale section. Items / bikes for sale here will be removed without warning. Reasons for this are in the FAQ. Thanks

Please can you post items for sale or wanted in the correct For Sale section. Items / bikes for sale here will be removed without warning. Reasons for this are in the FAQ. Thanks

-

peat61

- Settled in member

- Posts: 9

- Joined: Sun Jun 17, 2012 6:41 pm

Re: nc21 exhaust

fingers crossed i can come back on here and tell everyone its a great idea and everyone should do it, lol.

i spoke to a mechanic the other week and he said hed been in the trade for 20 years and had never come accross a bike where you had to drop the engine to remove the exhaust and wondered what honda were on when they thought of it.

i spoke to a mechanic the other week and he said hed been in the trade for 20 years and had never come accross a bike where you had to drop the engine to remove the exhaust and wondered what honda were on when they thought of it.

- CMSMJ1

- Moderators

- Posts: 7165

- Joined: Thu May 01, 2008 9:42 am

- Bike owned: NC30-No9

- Location: Chesterfield, United Kingdom

Re: nc21 exhaust

you pretty much have to drop the motor on a 21 or 24...

IMPERATOR REX ANGLORUM

The V4 is the law..

NC30 - No9 - my old mate

The V4 is the law..

NC30 - No9 - my old mate

-

peat61

- Settled in member

- Posts: 9

- Joined: Sun Jun 17, 2012 6:41 pm

Re: nc21 exhaust

well i did it!!

i cut the pipes at the straight bit before the final bend into the collector. i have had lots of issues with this but i think it has been a success.

1. cutter blade not long enough to get through the whole pipe, aarrgghhh had to drill it out a hole at a time until finished.

2. the pipe connector i ordered wasn't right. i had to cut it shorter and also do a full split down the side as there is a slight curve in the pipe at the point i cut it so it needed to be more flexible in the fit.

3. the front header pipes were a nightmare to get off. the flanges on both were ceased to the bolt, i managed to work one loose but the other was not playing ball and wouldn't come off for love nor money. only being able to get one pipe off was a pain but it did leave me with enough leway to do the job.

4.the connector clamps that came with the connector were thin and designed to fit at each end and seal it there, it now has a dirty great big slit all the way down now so had to cover that as well. i have seen a much better suited clamp on ebay which is a connector and clamp built into one which is a peice of steel which over laps this would be ideal for this job.

http://www.ebay.co.uk/itm/Universal-64m ... 3f18d92e99

5. it needs a bit of fiddling to get it to sit just right if its wrong the silencer wont fit back correctly.

the silencer and connector pipe have been resprayed black and look much better.

tommorow i will get it out and run her to see what happens, i will let you guys know.

i cut the pipes at the straight bit before the final bend into the collector. i have had lots of issues with this but i think it has been a success.

1. cutter blade not long enough to get through the whole pipe, aarrgghhh had to drill it out a hole at a time until finished.

2. the pipe connector i ordered wasn't right. i had to cut it shorter and also do a full split down the side as there is a slight curve in the pipe at the point i cut it so it needed to be more flexible in the fit.

3. the front header pipes were a nightmare to get off. the flanges on both were ceased to the bolt, i managed to work one loose but the other was not playing ball and wouldn't come off for love nor money. only being able to get one pipe off was a pain but it did leave me with enough leway to do the job.

4.the connector clamps that came with the connector were thin and designed to fit at each end and seal it there, it now has a dirty great big slit all the way down now so had to cover that as well. i have seen a much better suited clamp on ebay which is a connector and clamp built into one which is a peice of steel which over laps this would be ideal for this job.

http://www.ebay.co.uk/itm/Universal-64m ... 3f18d92e99

5. it needs a bit of fiddling to get it to sit just right if its wrong the silencer wont fit back correctly.

the silencer and connector pipe have been resprayed black and look much better.

tommorow i will get it out and run her to see what happens, i will let you guys know.

-

andy1472

- Settled in member

- Posts: 62

- Joined: Sat Apr 14, 2012 10:25 pm

- Bike owned: VFR NC21

Re: nc21 exhaust

Yes it can be done without removing the engine. Raise the sub frame and support it. Remove the shock and heat shield (support engine with a bit of wood on a trolley jack). You can get to all the nuts holding the headers in place but you will need a universal joint and a small extension bar to reach as the bolts are angled. Use a slim line socket as a normal sized diameter socket will be too fat to fit past the headers to get to the nuts. Been there and done it matey.

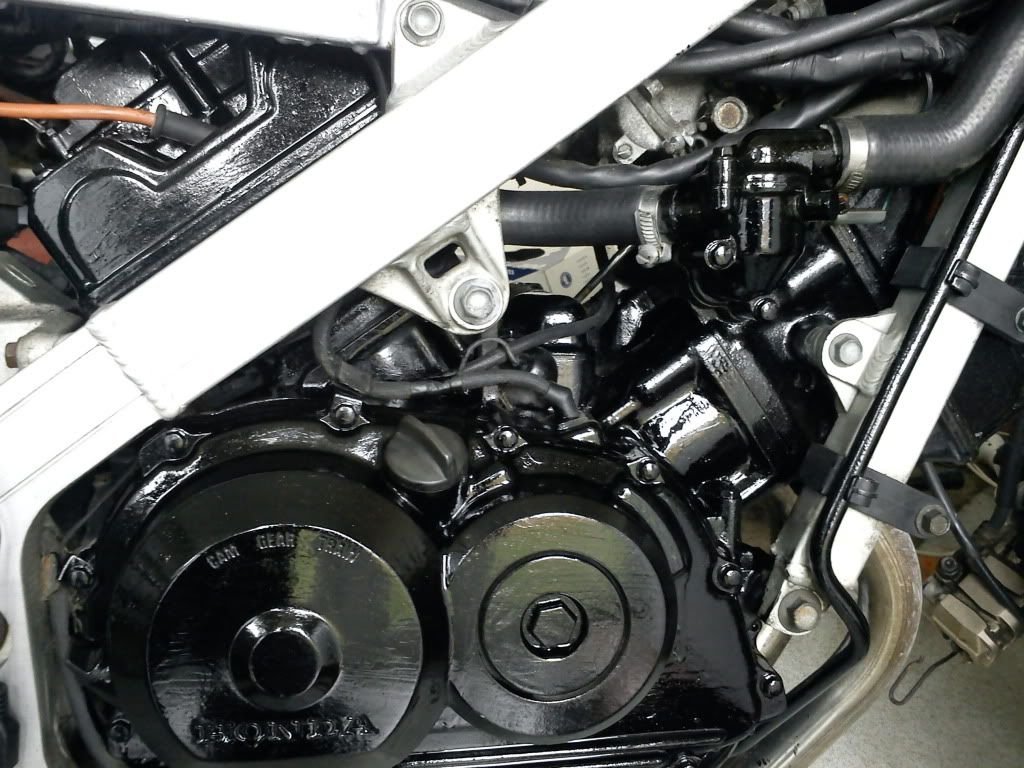

I brought a brand new collector off ebay for around £65. Cut the rear headers off (not on the bend but on the straight section on the horizontal plane. Don't cut and join behind the heat shield as your clamps to join the pipes back together will foul the shield stopping you from putting it back in). Put them back on the engine, put nuts back on (use copper grease) and new copper seals but did not fully tighten the nuts until the rest was aligned up. I brought some stainless tube, made my own connectors and clamps and offered up the new collector to the loose headers. All sealed and working lovely. NO NEED to remove engine. I have done it and taken photos of every step along the way. Listen to someone thats done it mate and not the guessers. I'll post you some pics in a bit when i remember my passord photobucket.

It's a simple engineering problem that is easily solved.

I brought a brand new collector off ebay for around £65. Cut the rear headers off (not on the bend but on the straight section on the horizontal plane. Don't cut and join behind the heat shield as your clamps to join the pipes back together will foul the shield stopping you from putting it back in). Put them back on the engine, put nuts back on (use copper grease) and new copper seals but did not fully tighten the nuts until the rest was aligned up. I brought some stainless tube, made my own connectors and clamps and offered up the new collector to the loose headers. All sealed and working lovely. NO NEED to remove engine. I have done it and taken photos of every step along the way. Listen to someone thats done it mate and not the guessers. I'll post you some pics in a bit when i remember my passord photobucket.

It's a simple engineering problem that is easily solved.

-

andy1472

- Settled in member

- Posts: 62

- Joined: Sat Apr 14, 2012 10:25 pm

- Bike owned: VFR NC21

Re: nc21 exhaust

Engine in, headers out.

Don't strap the sub to the roof. If you do it my way you can still move the bike if you need too.

Done