Tanto's New Redhead

- tanto

- Site Supporter

- Posts: 218

- Joined: Sat Oct 09, 2010 1:15 am

- Bike owned: NC30, Raleigh Chopper

- Location: Back in the UK.

Aluminum NC30 kickstand

The NC30's kickstand is awkward to use. Once removed from the bike it resembles a club, a heavy club. It's over engineered. It's ugly. It's time for a change.

The bracket is half the problem; like a Glaswegian bouncer, it's crude, strong, and over-weight. Trouble is, to build something better requires a CNC machine, which is something of a rarity in north Thailand. So my attention moved to the kickstand leg.

There's no question that a kickstand needs to be able to support the entire weight of the bike. Nonetheless an elegant leg - think Kate Beckinsale not Vin Diesel - should be possible, designed with the specs of the aluminum you're using and a brief calculation. Another rarity. In Chiang Mai aluminum is at best unspecified, at worst, recycled badly. Hence, the sturdy "Ann Widdecombe" thigh you see in the photo.

Advantages: About half the weight of the steel leg (weight to go here once it's, er, weighed), and an extra large foot to stop sinking into soft ground.

Disadvantages: None. It cost about GBP14 to make.

Question: What's the best design of stud, "shark's fin", or foot lever, you've seen on a kickstand leg? This leg needs one.

Last edited by tanto on Tue May 24, 2011 1:55 pm, edited 1 time in total.

"A slipping gear could let your M203 grenade launcher fire when you least expect it. That would make you quite unpopular in what's left of your unit." - US Army manual of preventive maintenance.

- tanto

- Site Supporter

- Posts: 218

- Joined: Sat Oct 09, 2010 1:15 am

- Bike owned: NC30, Raleigh Chopper

- Location: Back in the UK.

Cockpit Instrument Panel

Messin' around with aluminum...

Front

Rear

This is the prototype of an adjustable, lightweight cockpit instrument panel for the NC30. By building it in a modular way, it is possible to replace each part of the unit with carbon fiber or titanium parts in the future.

The bare metal awaits further drillings for instrument lights, switches, etc.. The instrument panel is designed to attach to an aluminum front spar (already made). I'm experimenting with different ways of securing the two.

As for the final finish, it's either going to be matt black powder coat (practical), or brushed aluminum ( ). Any preferences?

). Any preferences?

Edit 3 March: "JB" on the forum, says that his steering damper could interfere with the standard instrument panel, depending on the set-up. The cut-away rear panel might solve this problem.

Front

Rear

This is the prototype of an adjustable, lightweight cockpit instrument panel for the NC30. By building it in a modular way, it is possible to replace each part of the unit with carbon fiber or titanium parts in the future.

The bare metal awaits further drillings for instrument lights, switches, etc.. The instrument panel is designed to attach to an aluminum front spar (already made). I'm experimenting with different ways of securing the two.

As for the final finish, it's either going to be matt black powder coat (practical), or brushed aluminum (

Edit 3 March: "JB" on the forum, says that his steering damper could interfere with the standard instrument panel, depending on the set-up. The cut-away rear panel might solve this problem.

Last edited by tanto on Tue May 24, 2011 1:54 pm, edited 1 time in total.

"A slipping gear could let your M203 grenade launcher fire when you least expect it. That would make you quite unpopular in what's left of your unit." - US Army manual of preventive maintenance.

- tanto

- Site Supporter

- Posts: 218

- Joined: Sat Oct 09, 2010 1:15 am

- Bike owned: NC30, Raleigh Chopper

- Location: Back in the UK.

Front Brake Calipers

Dang! Two weeks of stripping, cleaning, and re-building the front brake calipers has resulted in limited success. Installed and bled, the calipers firmed up okay, but the pistons fail to release. With the brakes permanently "on", it's time to strip down the master cylinder...

What have I learned?

- Despite advice to the contrary, break the calipers in two. Cleaning the piston cylinders while the calipers are together is time-consuming, and very difficult. If the cylinders are corroded or embedded with stubborn black stains from worn out seals, they are very hard to clean properly. Split the calipers, and save hours.

- When powder-coating the calipers, mask off all four sides of the brake pad contact area, not just the broad longitudinal faces. There's a nagging suspicion at the back of my mind that the brake pads could be hanging up on the powder-coat along the small lower edges (where the lower edges of the brake pad frames might touch).

- When powder-coating the calipers, don't powder-coat the top of the torx bolts so the E12 socket won't fit without hammering, thereby ruining the finish...

The good news? Semi-gloss black is a good colour for brake calipers.

What have I learned?

- Despite advice to the contrary, break the calipers in two. Cleaning the piston cylinders while the calipers are together is time-consuming, and very difficult. If the cylinders are corroded or embedded with stubborn black stains from worn out seals, they are very hard to clean properly. Split the calipers, and save hours.

- When powder-coating the calipers, mask off all four sides of the brake pad contact area, not just the broad longitudinal faces. There's a nagging suspicion at the back of my mind that the brake pads could be hanging up on the powder-coat along the small lower edges (where the lower edges of the brake pad frames might touch).

- When powder-coating the calipers, don't powder-coat the top of the torx bolts so the E12 socket won't fit without hammering, thereby ruining the finish...

The good news? Semi-gloss black is a good colour for brake calipers.

"A slipping gear could let your M203 grenade launcher fire when you least expect it. That would make you quite unpopular in what's left of your unit." - US Army manual of preventive maintenance.

-

karl BKK

- Settled in member

- Posts: 195

- Joined: Wed May 19, 2010 12:17 pm

Re: Tanto's New Redhead

The bike is coming alone nicely mate.

Mine on the other hand was sold around 3 months ago for 8k less than i paid for it and needing a new rear tyre, headgasket, possibly rings and a hone too, new chain as it snapped and smashed the gearbox case. Then i sold the original fairings for 12,000 baht, so i didn't do to bad in the end.

I'll be buying a Yamaha R6 next week if all goes to plan, so i'll be signing out of here mate.

Mine on the other hand was sold around 3 months ago for 8k less than i paid for it and needing a new rear tyre, headgasket, possibly rings and a hone too, new chain as it snapped and smashed the gearbox case. Then i sold the original fairings for 12,000 baht, so i didn't do to bad in the end.

I'll be buying a Yamaha R6 next week if all goes to plan, so i'll be signing out of here mate.

- tanto

- Site Supporter

- Posts: 218

- Joined: Sat Oct 09, 2010 1:15 am

- Bike owned: NC30, Raleigh Chopper

- Location: Back in the UK.

Re: Tanto's New Redhead

Karl, sorry to see you go, mate. Dropped my contact details in your email. Do get in touch if you head up to Chiang Mai. Not sure if we're going to miss you or your g'friend more:

On second thoughts, I am sure... Good luck with the R6!

Good luck with the R6!

On second thoughts, I am sure...

"A slipping gear could let your M203 grenade launcher fire when you least expect it. That would make you quite unpopular in what's left of your unit." - US Army manual of preventive maintenance.

- tanto

- Site Supporter

- Posts: 218

- Joined: Sat Oct 09, 2010 1:15 am

- Bike owned: NC30, Raleigh Chopper

- Location: Back in the UK.

Re: Tanto's New Redhead

My first post for two months. What have I been doing? The short story? The bike runs, and she runs like a champ. The long story I'll document below.

Meanwhile, I've just re-hosted the photos, so all the images should be viewable. More to follow...

Meanwhile, I've just re-hosted the photos, so all the images should be viewable. More to follow...

"A slipping gear could let your M203 grenade launcher fire when you least expect it. That would make you quite unpopular in what's left of your unit." - US Army manual of preventive maintenance.

- tanto

- Site Supporter

- Posts: 218

- Joined: Sat Oct 09, 2010 1:15 am

- Bike owned: NC30, Raleigh Chopper

- Location: Back in the UK.

Tanto's New Redhead - Rear Overhaul

Where were we? The beginning of Week 8 of my NC30 rebuild and, with a front master cylinder repair kit on order, it was time to strip and overhaul the rear of the bike.

A lovely looking original swing-arm in an authentic unwashed state.

Rather than strip the entire bike in one go, I prefer to work on one section at a time. That way, there's a better chance I'll remember how it goes together.

All of the bearings were replaced in the rear hub. Thanks again to NTN in Chiang Mai.

I was surprised at the weight of the rear hub assembly, and made a mental note of ways to reduce it in the future. Namely, fit a Ducati style RHD hub nut, and an alloy rear sprocket. I'm tempted by an alloy RS250 rear hub, too, but concerned about it's strength and durability, and whether the Ducati "nut mod" might not weaken the hub.

A lovely looking original swing-arm in an authentic unwashed state.

Rather than strip the entire bike in one go, I prefer to work on one section at a time. That way, there's a better chance I'll remember how it goes together.

All of the bearings were replaced in the rear hub. Thanks again to NTN in Chiang Mai.

I was surprised at the weight of the rear hub assembly, and made a mental note of ways to reduce it in the future. Namely, fit a Ducati style RHD hub nut, and an alloy rear sprocket. I'm tempted by an alloy RS250 rear hub, too, but concerned about it's strength and durability, and whether the Ducati "nut mod" might not weaken the hub.

"A slipping gear could let your M203 grenade launcher fire when you least expect it. That would make you quite unpopular in what's left of your unit." - US Army manual of preventive maintenance.

- tanto

- Site Supporter

- Posts: 218

- Joined: Sat Oct 09, 2010 1:15 am

- Bike owned: NC30, Raleigh Chopper

- Location: Back in the UK.

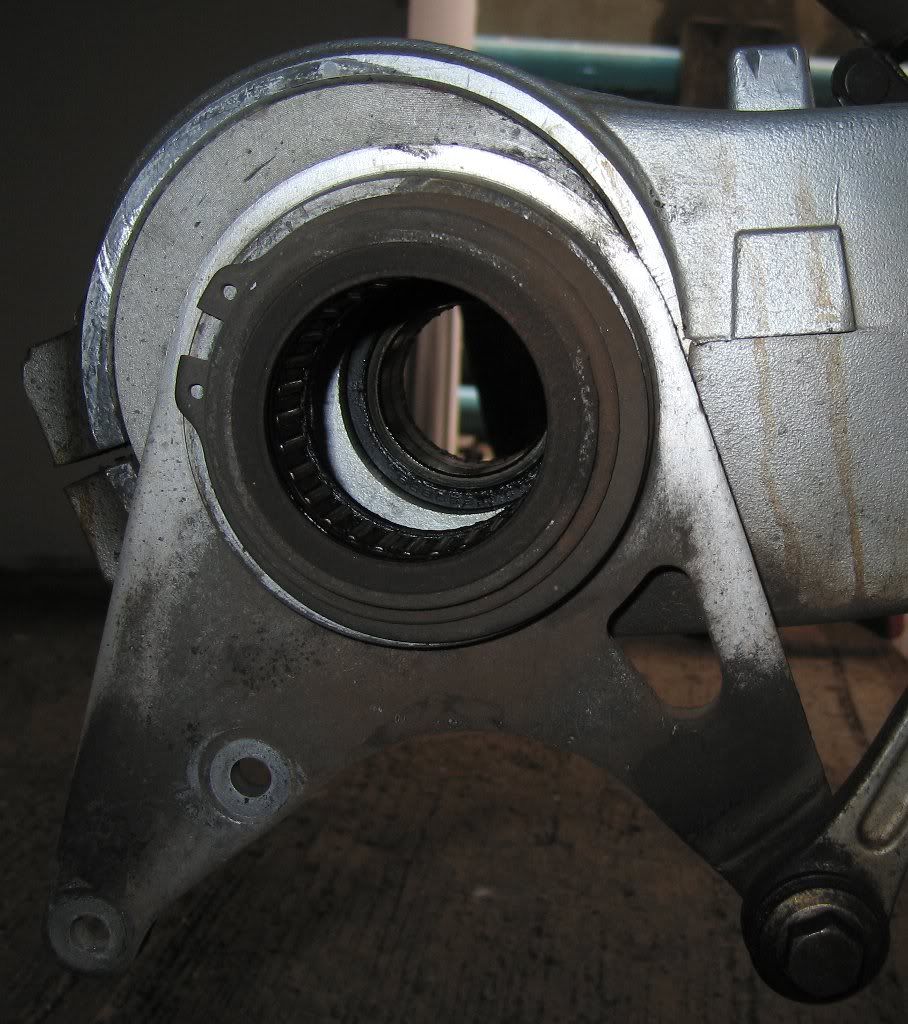

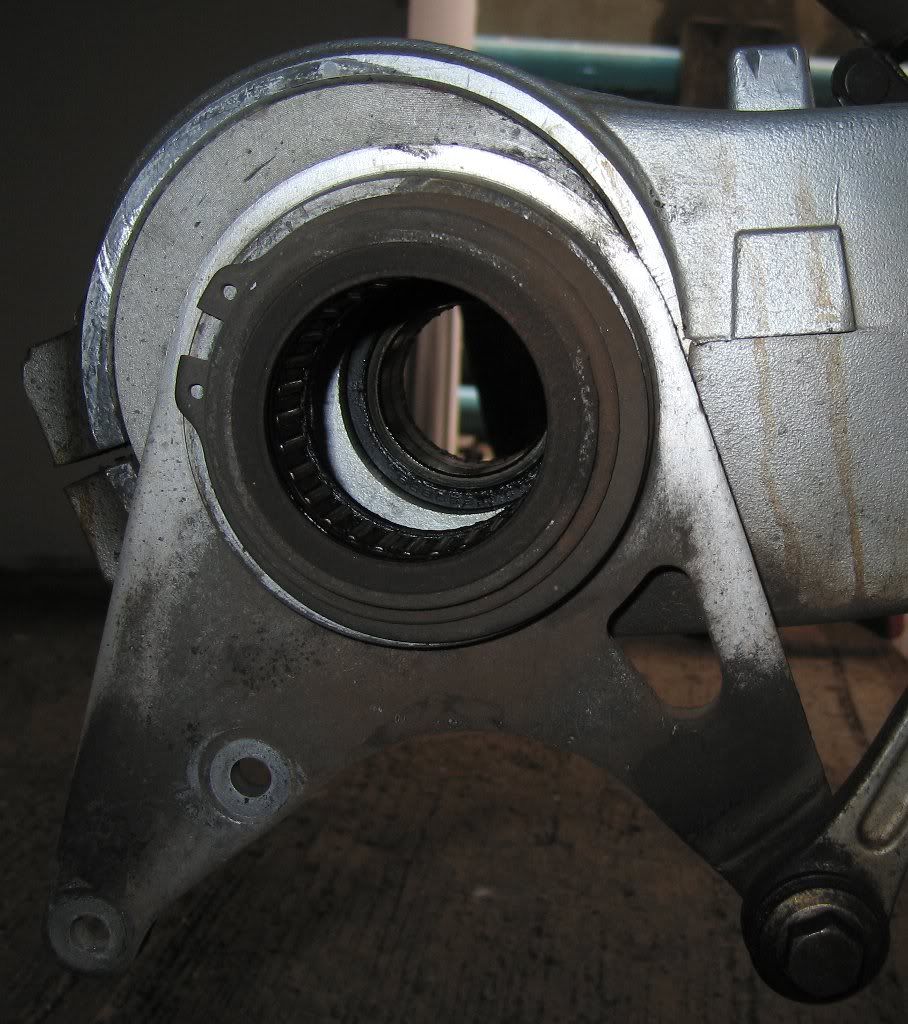

Tanto's New Redhead - Rear Hub Overhaul

On inspection, the rear hub - the part that rotates inside the rear of the swingarm - was catching on some scores in the light alloy. As half the rear adjustment teeth had been broken off, I had already ordered a new hub from the UK (thanks Geoff33!). Rotating it in the swingarm by hand soon revealed the gouges and burrs that were causing a problem. Two minutes work with a metal file and the hub was rotating without catching. Then I thought, why not polish the tracks on the inside of the swingarm? The alloy is so soft, they responded quickly to an application of Wet'n'Dry 300/600/800/1000/2000 & smidgen of metal polish. Not too much, mind you, as they need to grip more than slide.

Better was to follow with the installation of the new hub, bearings, rear brake disc from Hong Kong, stainless steel fittings, and Goodridge rear brake cable. And I overhauled the rear brake with new piston seals, ultrasonically cleaned and lubed the slider, repainted the body, and slipped in some EBC HH sintered brake pads, too. A Tyga carbonfiber chainguard was the final detail.

"A slipping gear could let your M203 grenade launcher fire when you least expect it. That would make you quite unpopular in what's left of your unit." - US Army manual of preventive maintenance.

- tanto

- Site Supporter

- Posts: 218

- Joined: Sat Oct 09, 2010 1:15 am

- Bike owned: NC30, Raleigh Chopper

- Location: Back in the UK.

Tanto's New Redhead - Carbonfiber Chainguard

With the rear of the bike apart, I dropped the rear shock into "Shock-Up!" in Chiang Mai. A difficult to find (read, no signage in English) car shock absorber specialist, recommended by Tom who runs "G3" (G3 BIKE SHOP, 98/2 Taiwang Rd., T Chang Moi, Chiang Mai, tel: 053-233600 & 09-2621334, close to Nawarat Bridge สะพานนวรัฐ), they run a sideline in motorcycle shock servicing.

What does the man who arrives with an old Showa shock in his hand want? Jokes aside, the man at Shock-Up! told me to come back in a couple of days. Twenty-odd quid in the local equivalent, and the shock had new washers, bladder, fluid, and a gas fill, and the addition of a schrader gas valve in the remote oil reservoir.

"A slipping gear could let your M203 grenade launcher fire when you least expect it. That would make you quite unpopular in what's left of your unit." - US Army manual of preventive maintenance.

- tanto

- Site Supporter

- Posts: 218

- Joined: Sat Oct 09, 2010 1:15 am

- Bike owned: NC30, Raleigh Chopper

- Location: Back in the UK.

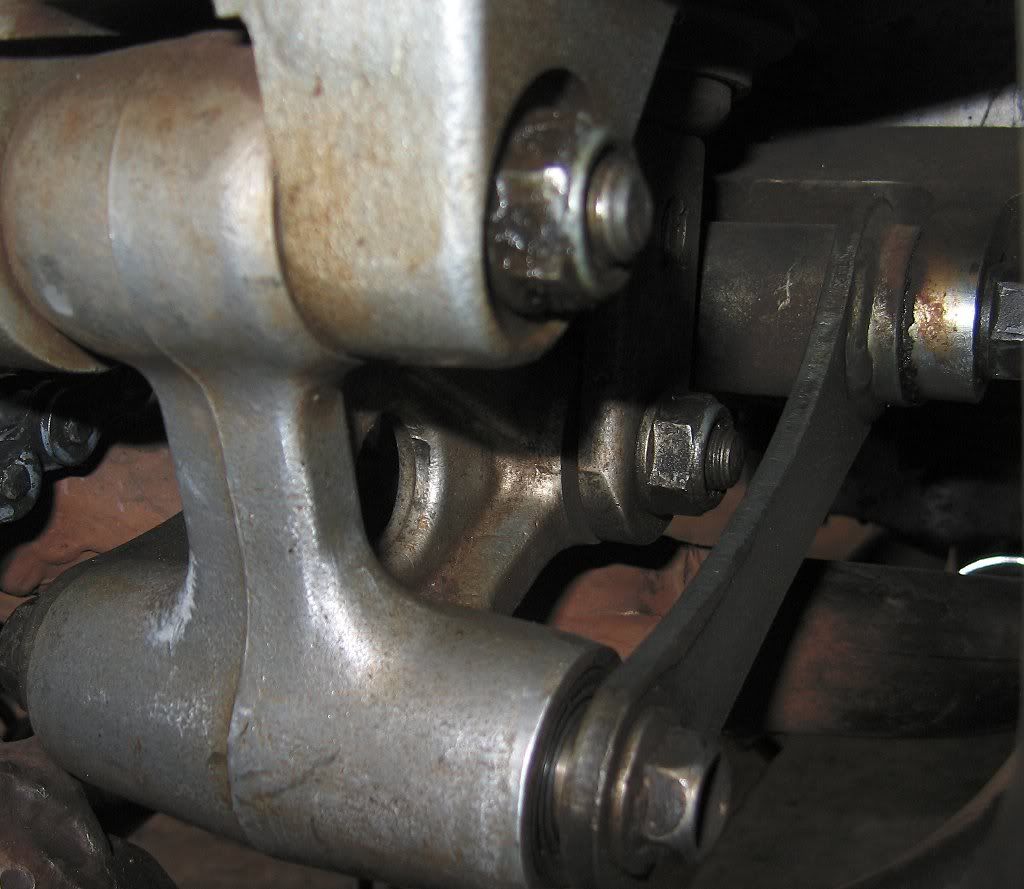

Tanto's New Redhead - Suspension Linkage Mod

Dismantling the rear suspension linkages apart was straightforward. Apart from a good clean, what I wanted to do was replace the rubber bushing in the triangular suspension/shock linkage with a roller bearing. The Honda RVF / NC35 has a roller bearing in the same place as standard.

All that was required was to push out the old rubber bushing, drill the linkage out from 20mm to 24mm, and fit the RVF parts.

- 91071-MY1-005 - Needle Bearing (17×24×17)

- 52465-MY1-000 - Pivot Pin

- 91262-KV3-831 - Dust Seal (17×24×5). You'll need two of these.

The advantage of this mod is that it enables the rear suspension to move more freely. A further benefit is that this freedom of movement makes re-assembly much easier than the stock unit.

All of the other suspension bearings were replaced with new NTN bearings and packed with grease. The suspension linkage nuts were replaced with stainless steel nyloc nuts.

"A slipping gear could let your M203 grenade launcher fire when you least expect it. That would make you quite unpopular in what's left of your unit." - US Army manual of preventive maintenance.