Well I haven't gone down the route I mentioned in my last post, no rear-sets or single seat conversion.

But I have done a few little bits with more to come after Christmas.

I moved base again in October and the motorbike club here has a fully outfitted workshop, big win

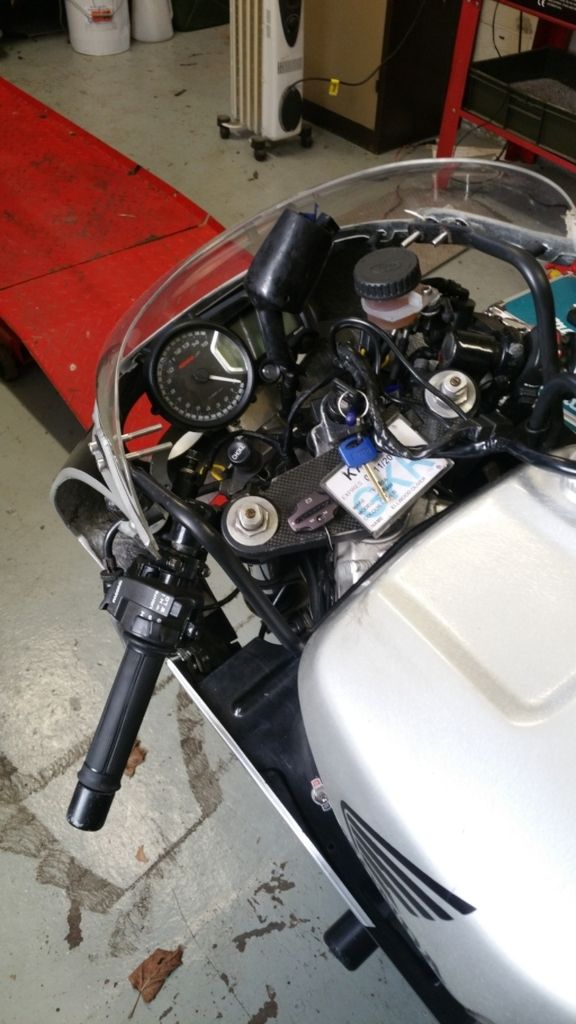

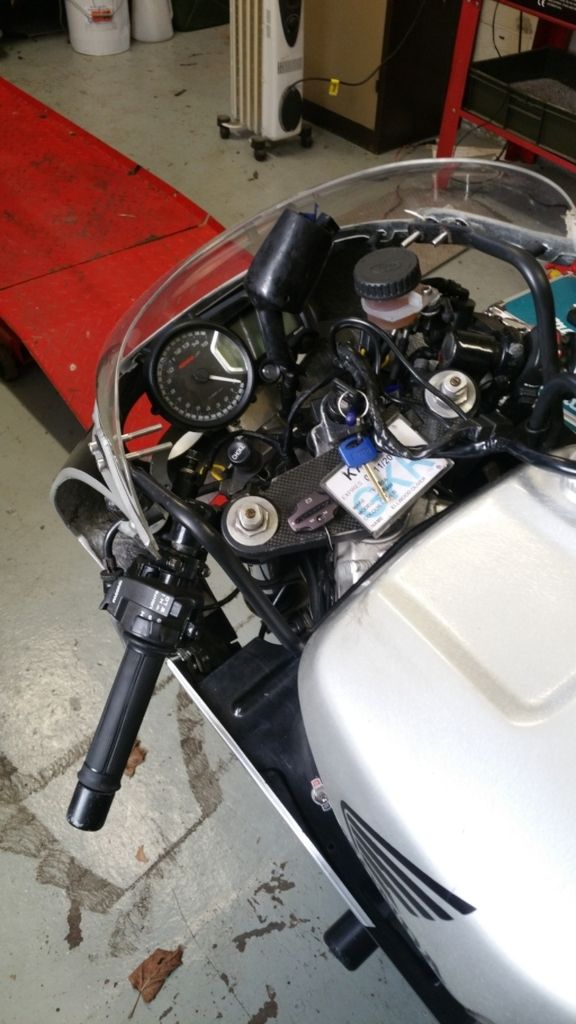

Got the bike up onto the ramp and started stripping the front end ready for a new clock/headlight bracket, screen brace and modification to the speedo bracket I made a couple of months ago.

The bracket needed lowering on the mounting to allow the clutch to clear properly as before it was catching and nudging the clocks. Luckily the club have a pillar drill, but unluckily they don't have a small handheld vice so mole grips were put into inappropriate use....

Nose cone back on and checking for clearance.

Then I changed the screen brace for a lovely SES aluminium one as I'm becoming a bit of a tart....

On and checking to see that everything lines up as it should.

I also got myself a hydraulic conversion off a member on here (can't remember who sorry!)

It was as expected a bit grubby as it'd come off another bike, so once I'd dissembled and cleaned up I could see what if any parts I'd need to order.

Iv'e ordered a new gasket to go between the slave unit and the sprocket/clutch cover, a new o-ring seal for the slave end of the clutch push rod, plus a couple of bits for the m/c which I'll come on to later.

All cleaned up I re-assembled the slave unit with a good layer of rubber grease and it slides lovely now.

Unfortunately when it came to making sure the bleed nipple actually moved it just didn't. And it snapped

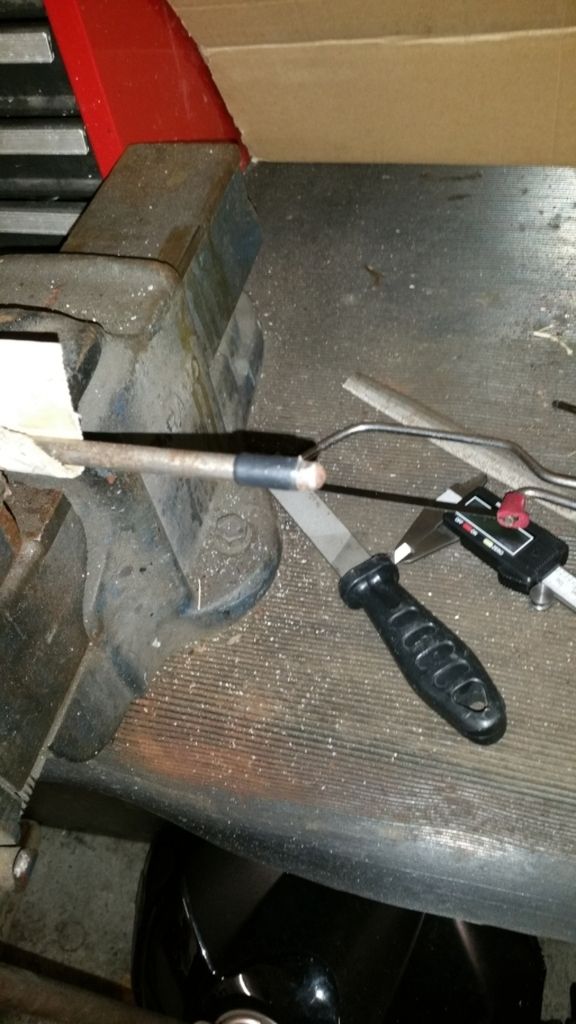

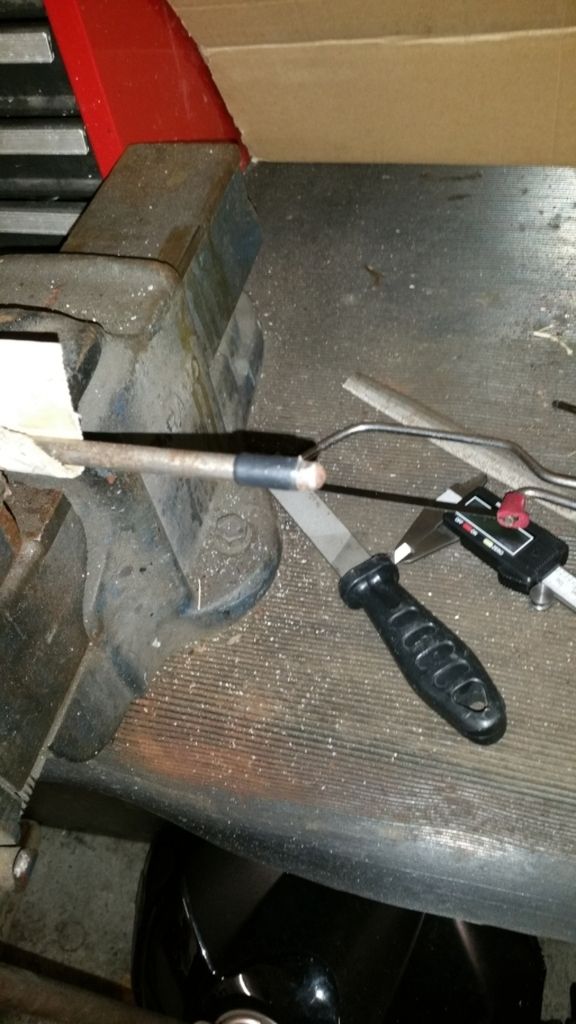

So back to using the pillar drill again....

I unbolted one of the vices from the bench and just about made it work under the drill.

All drilled out I pulled some of the thread spiral from the nipple out but had to tap the rest.

Next job was to shorten the VFR750 clutch push rod I had to 339mm as per the clutch conversion thread.

3 junior hacksaw blades later and this tough bugger was finally cut.

I made use of yet another of the clubs tools and created a rounded edge after the cut to prevent damage to the slave seal.

Here's the difference between the two rods, the NC30 one being shorter.

Fitted up the slave cylinder onto the cover and connected up my new Hel line (matches my brakes, I know, tart).

I then attached the SP2 m/c to the left bar and connected up the other end of the line. I am still waiting on a new reservoir cap, lever, lever push rod and bush, plus the gasket and seal before I can bleed up the system.

I didn't take any photo's of the m/c as I forgot but after Christmas I shall have a lovely set of CNC adjustable levers and SES aluminium clip-ons to finish it all off

One last job was to balance the carbs as the idle was a little rough, luckily the club also has a carb balance kit! Brilliant place this.

Didn't get a pic of vid of me actually balancing them up as I was too pre-occupied with the engine gently roasting my right hand while adjusting the carbs.

Other update is that I have removed the alarm from the wiring loom as it was causing a 7A drain on the battery.

The difference to the bike was very noticeable after I had taken it out, started easier and ran better. Plus it doesn't need to be left on charge anymore

The bike will be staying in the dry and slightly warmer than outside club garage until the spring when I get back on some more trackdays!

Next will be finishing off what I have mentioned, fitting some wet tyres to my newly acquired spare set of wheels, spacing over the chain so I can run 160's and maybe a Q/A throttle.

I might even get round to that single seat conversion....