Page 2 of 6

Re: Nc30 rescue

Posted: Sat Oct 17, 2015 12:12 pm

by pptom

Also blasted and painted the yokes, Clip on brackets, sump and rear brake torque assembley.

Gloss black is Simoniz Engine Enamel,

Matt black top yoke is P1J

Silver is Simoniz Engine Enamel

Re: Nc30 rescue

Posted: Sat Oct 17, 2015 12:15 pm

by pptom

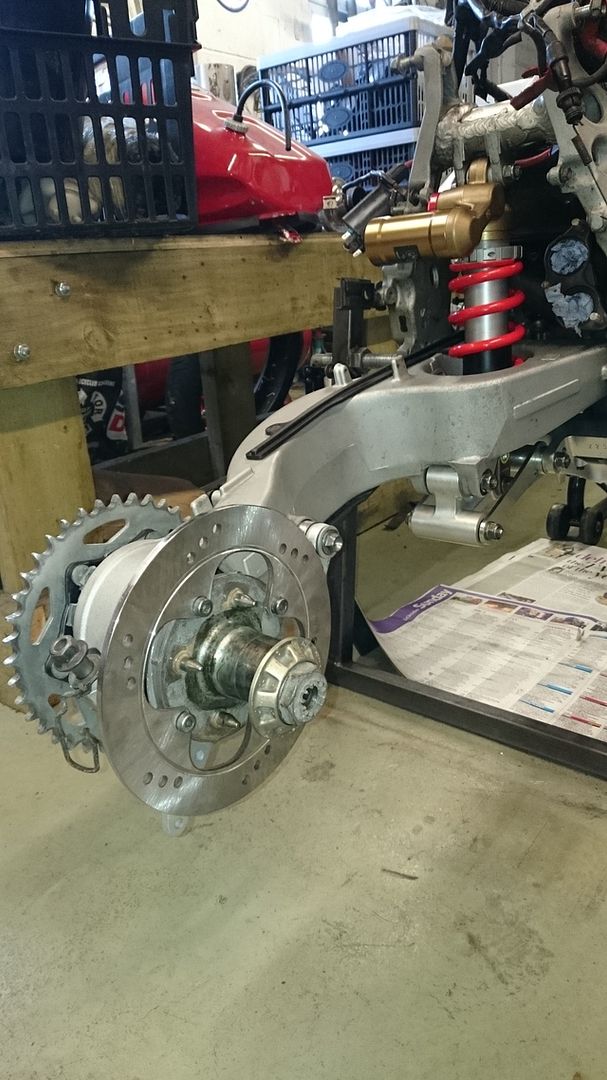

I knew the rear disc was a bit thin, so ordered a replacement, while I was removing the bolts from the old disc today I noticed this:

On closer inspection it looks like there is cracks in similar places all round the disc - could have been nasty!

Only issue with the new disc is that its a bit thicker than the original at the mounting points, meaning the original bolts are about 3mm too short so they don't fully engage with the end of the nuts

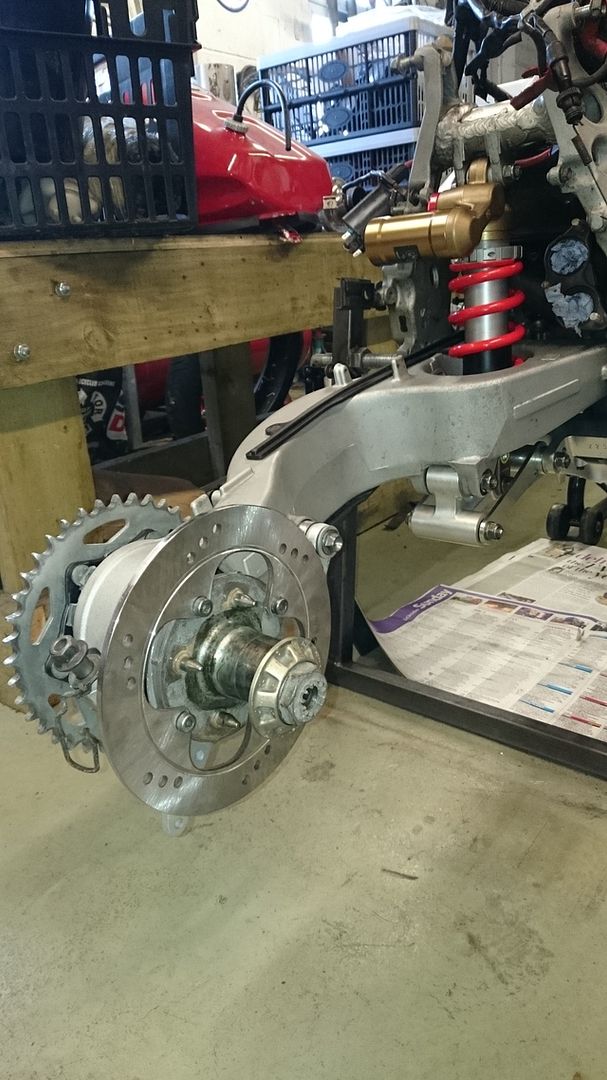

Cleaned up and re-fitted the rear hub, looking more like a bike again, :

Re: Nc30 rescue

Posted: Sat Oct 17, 2015 3:27 pm

by micpec

Is that a bmw shock with hrc linkage?

Re: Nc30 rescue

Posted: Sat Oct 17, 2015 4:28 pm

by pptom

Yes mate, very low miles shock and linkage was less money than a bog standard Nitron and has way more adjustability, that was my reasoning anyway.

Re: Nc30 rescue

Posted: Thu Oct 22, 2015 7:13 pm

by pptom

Been busy with my ebay cut system, the front collars were non existant and the whole thing was pretty grotty.

Scrounged a couple of small lengths of 1 1/2" stainless tube and some filler rods off of a mate for a pint, I ground out the old mild steel inserts:

Then cut the new pipe to length and Tig welded in place, My first go at welding stainless, its not visually perfect, but not so bad:

I then polished up the rest of the system (did the visible parts more than non visible) and fitted along with new gaskets all round:

Not bad for £18 inc link pipe! The trouble is that with the newly painted side covers, polished exhaust and painted sump, it really shows off the tired bits of the engine. At the moment I don't think there's any value in pulling the engine out to tart it up, especially as it will mostly be used as a track bike. I'll wait until it has to come out.

Just need to score another length of pipe and I can do my standard system prior to storage.

Cleaned and rebuilt the carbs the other day, parts from Rick O include some 1mm needle shims, 118 / 120 mains and a liketek o ring kit. All floats checked - had to adjust one by about a mm. Curiously the holes in the slides are already 3mm (the guide states drill out to 2.5?) Just need to bench balance them, I'll probably also do them by vacuum when on the engine.

They weren't in too bad nick, except all of the screws which anchor them together were loose, so they must have been miles out of synch when last run.

Re: Nc30 rescue

Posted: Thu Oct 22, 2015 9:49 pm

by vfrman

Your welds look better than the stock ones at the y...

Re: Nc30 rescue

Posted: Thu Oct 22, 2015 10:20 pm

by royster81

Fancy doing another ?!

Re: Nc30 rescue

Posted: Fri Oct 23, 2015 6:19 pm

by pptom

You're probably better off finding someone local, postage would be a pain and expensive. I know a guy who has a fabrication business would have probably done it for £15 cash, but fancied having a go myself. There's lots of these little gems about, they just have to be sought out, most aren't online, its just word of mouth. There's a few of us bikers who know each other in town, most into old bikes, and i've got alot of contacts through them. Get plating done in exchange for beer, machining in exchange for welding etc.

Re: Nc30 rescue

Posted: Sat Oct 24, 2015 7:37 pm

by pptom

Today I've been mostly rebuilding the rear caliper and blasting / painting stuff.

Starting with the coolant system. Someone along the line had fitted an Ally drain plug to the water pump cover which naturally sheared when I tried to remove it

I drillet it out and fitted an M6 helicoil

As you can see, the covers were a little manky

So they went for a trip to the blasting cabinet

Then got painted with Simoniz engine enamel

Re: Nc30 rescue

Posted: Sat Oct 24, 2015 7:42 pm

by pptom

I fitted the refurbed subframe and dug the exhaust bracket out

Its seen better days, so I used a scotchbrite wheel on my die grinder, followed by a session on the polishing wheel