I've made up a worksheet in Excel to assist with calculating and recording valve adjustment for the NC30 and NC35. I can't claim this as an original idea, I adapted it from a similar worksheet on an SP1/SP2 forum, however I have made some modifications and what I think are improvements and added a linked sheet for use as a record. Props to Rick Oliver for helping with some of the Honda shim numbers.

Here's the link to download the file:

http://www.sendspace.com/file/tvvm37

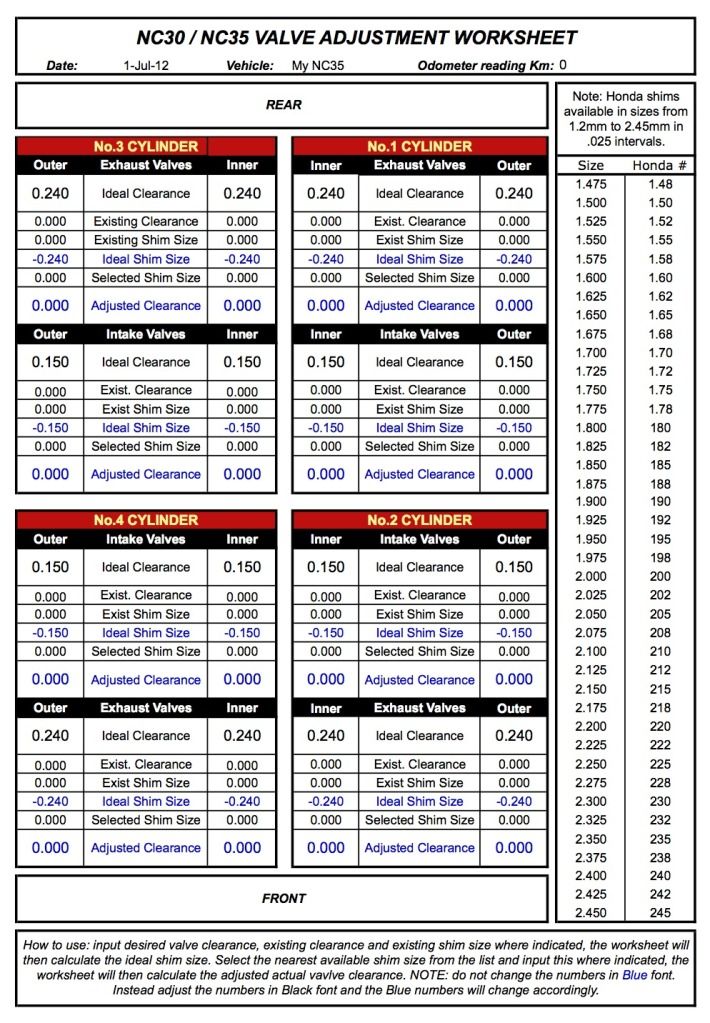

This may look a bit intimidating but really it's very easy to use:

1/ first input your desired ideal valve clearances. I've set these provisionally at .15 Inlet and .24 Exhaust (mid point in the range for street clearances) but you can change these to whatever you prefer, obviously people with track bikes will want to set these to larger tolerances.

2/ go through and measure and record the existing clearances and existing shim sizes for each valve and input these. The worksheet will then calculate the ideal shim size required to give your desired ideal clearance.

3/ select the nearest available shim sizes from the column on the right-hand-side and input these, the worksheet will then calculate the adjusted clearances based on your selection. The worksheet makes it very easy to see the results of experimenting with different shim sizes.

Only one word of caution: do not change the numbers in Blue font in the worksheet, you'll corrupt the formulas if you do. Instead change the numbers in Black font and the Blue numbers will change accordingly. If you do corrupt the file don't worry, delete it and start again.

Once you're done on the first sheet click on sheet 2 "Valve Adjustment Record". You'll see your measured final clearances and shim sizes have been recorded here. If you input the date and a description of the bike on the first sheet that info will be copied to this page also. Additionally if you input your odometer reading on the worksheet the record will tell you when next to check the clearances (in kilometers). Print the record or save as a .pdf file for use in the future.

Obviously real world practice can be different to theory. In my experience is once the motor has been turned over a few times measured clearances can change slightly. Nevertheless I've found this worksheet to be a useful tool, I am pretty pedantic about obtaining the most accurate and consistent clearances possible. Considering the amount of hassle in adjusting the clearances on our bikes is there any other way to be?

Jimmy